We have analysed our 'scope 3 emissions'. These are emissions that are created throughout the supply chain. There are 15 categories used within the GHG protocol, which is a global standard of measurement. They include emissions from activities like business travel, waste generation and customer use of products. While many of these emissions are influenced by us, they are not under our direct control, so part of the solution is to form strong partnerships with our suppliers so we can have a role in reducing them.

We found the biggest scope 3 emissions occurred in customer use. This is mainly due to the heating of water in homes and commercial properties.

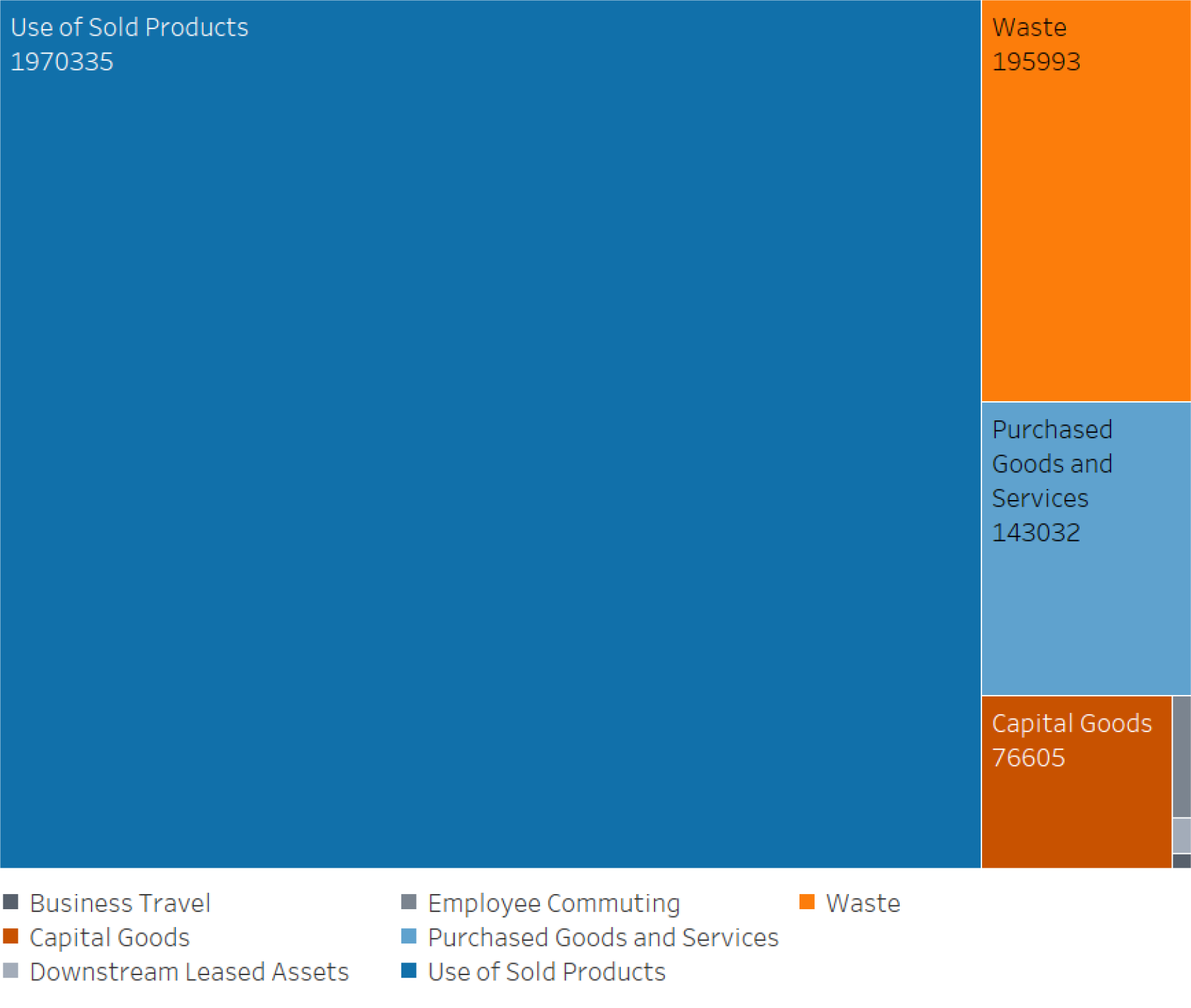

The findings are summarised in the graph below:

Heating water in homes and businesses makes up 81% of our scope 3 footprint. Yorkshire Water recognise the need to support customers in reducing their own carbon footprints while saving water. This was an unexpected finding which highlighted the need to join up customers, energy and water companies with the manufacturers of white goods and cleaning products to help reduce emissions. We are exploring ways we can work with partners to further support our long-standing focus on water efficiency.

Yorkshire Water also want to stay focused on emissions we can influence and these related to 3 key areas: Waste generated in our operations (195 ktCO2e), electrical and mechanical goods (69 ktCO2e) and chemicals used in our processes (24 ktCO2e).

These three areas were chosen, not only because of their emissions, but as something we could influence and improve.

We now have a performance commitment to deliver more value from waste which should drive the associated emissions down. We have also conducted more analysis of our chemical use to see if we can switch chemicals or use different processes to reduce our emissions. Further work is also being considered around how we can calculate and reduce emissions from our maintenance programme, which will support a reduction in electrical and mechanical goods emissions.